Photocatalytic High-Order Oxidation Equipment

Introduction to higher order oxidation procedures

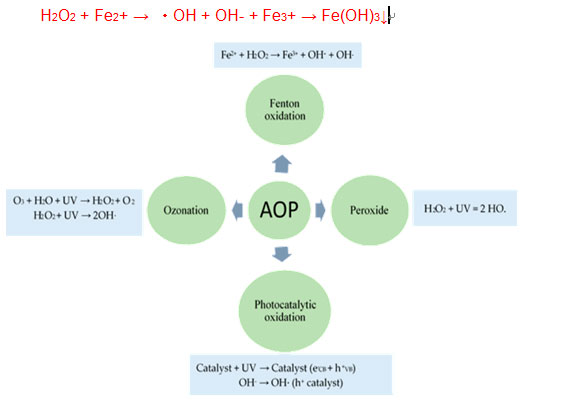

Advanced oxidation technology, also known as deep oxidation technology (Advanced Oxidation Processes; AOPs), is based on the use of electricity, light irradiation, catalysts, and sometimes combined with oxidants to produce extremely active free radicals (such as HO•) during the reaction. Then through the adduction, substitution, electron transfer, bond breaking, etc. between free radicals and organic compounds, the macromolecules in the water that are difficult to degrade are oxidized and degraded into low-toxic or non-toxic small molecular substances, or even directly decomposed into CO2 and H2O. Chemical oxidation technology is often used as a pretreatment for biological treatment. It generates hydroxyl radicals during the reaction as follows:

Product features

1. The system is equipped with a waterproof quartz casing that can be directly immersed in water to improve the utilization of UV light radiation.

2. Advanced oxidation equipment such as electrolysis catalysis and photocatalysis can be used with oxidants, catalysts, photocatalysts, etc. to construct advanced oxidation treatment and air purification and efficient treatment systems.

3. Solve the problem of water quality that is difficult to decompose chemically or biologically.

4. The equipment is highly efficient and easy to maintain, operate and manage.

5. It can improve the treatment effect of COD, ammonia nitrogen and nitrate nitrogen.

6. It can improve the ability of biological digestion and degradation of BOD/COD.

7. The material corresponds to SUS304/316/2205/PP/Ti.

8. It has low secondary pollution and is friendly to the environment. After treatment, it is unlike other chemicals such as bleach (sodium hypochlorite), which can easily produce toxic substances such as chlorinated organic matter and cause harm to the environment.

9. It occupies a small space. Since the oxidation reaction is very fast, the required residence time is short. About 0.5 to 2 hours of reaction is enough, while general biological treatment takes about 12 to 24 hours. Due to the short residence time, the volume of the reaction tank does not need to be too large, thus saving space.

10. The operation is highly flexible. Within the design allowable range, the treatment system can handle higher polluted water quality by simply adjusting the parameters or setting operating conditions according to the incoming water quality to increase the treatment capacity. However, it is difficult for general biological treatment to have flexible operating space.

11. Drug addition and system operation can be automatically controlled and processed, greatly reducing the burden on operators.

12. Compared with the biological treatment system, it only requires 1/3~1/4 of its investment cost.

13. It has strong oxidizing power. The hydroxyl radical (‧OH) generated by catalysis has very strong oxidizing power and can handle a variety of toxic substances such as vinyl chloride, BTEX, chlorobenzene, 1,4-Dioxane, aldehydes, pentachlorophenol, and polychlorinated biphenyls, TCE, DCE, PCE, EDTA, ketones such as MTBE, MEK...etc.

Application scope

It can be used in advanced oxidation treatment, sewage treatment, water sterilization, air sterilization, COD degradation, BOD degradation, wastewater defoaming, etc. Suitable for various pools, aquariums, fish ponds, swimming pools, building cooling towers, food industry, and factory wastewater treatment.

Performance cases

Diverse specifications and customization

The products can provide planning services and professional technology to solve customer problems according to the different needs of customers.

繁體中文

繁體中文 English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk